TPV Flame Retardant

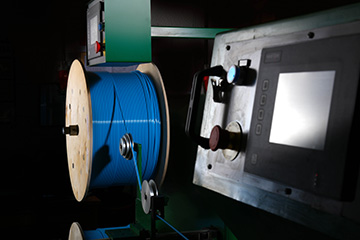

As a leading manufacturer of polymeric liners for the automotive control cable market, our mission has always been to be at the forefront of technical advancements in the field of plastic extrusion products for the automotive industry, constantly researching new technologies and developing them where they fit best with our core market.

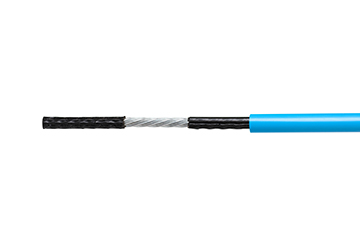

Our automotive control cable liners are manufactured from technically advanced fluorinated polymer compounds that are the result of an extensive R&D programme.

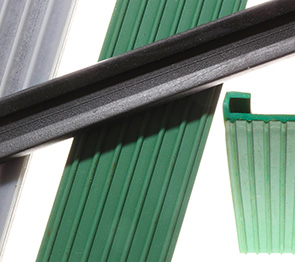

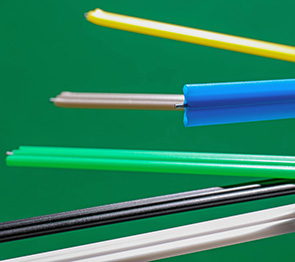

This has led to our recent introduction of low friction Fluor-TEP liners for the control cable market, this range of liners can have either a smooth internal surface, or where a higher sliding resistance characteristic is required the internal surface may be corrugated.

FluorTEP is a generic name for our family of fluorinated polymer compounds specifically formulated and developed for the control cable liner market and these compounds enable products to be manufactured that offer performance benefits in a number of important areas.

FluorTEP

FluorTEP is a thermoplastic fluorinated polymer alloy in which the durability and attrition resistant PBT base polymer has been modified by the incorporation of fluorinated additives. In this way, products extruded using FluorTEP compound not only demonstrate excellent durability but also enhanced sliding resistance and this leads to a longer component service life.

The friction performance of FluorTEP can match that of the filled PTFE compounds currently used for automotive components. The temperature resistance threshold for most automotive control cable liners is 120°C and this temperature is within the performance characteristics of FluorTEP. Consequently, the high temperature resistance, cost effectiveness, durability and recyclability of FluorTEP position our material as the perfect choice to meet target industry needs and requirements, as a competitive alternative to using Thermoset compounds, including PTFE.

Another advantage of the FluorTEP polymer is the easy processability compared to PTFE.

The properties described below provide an illustration of the physical and commercial advantages of Piltec automotive control cable liners.

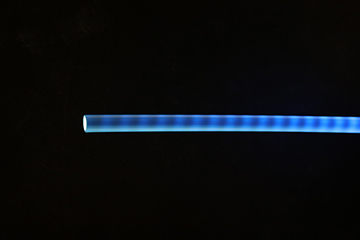

To meet specific automotive standards, our up-to-date production equipment is fitted with the latest continuous in-line laser sizing equipment and as a result of this technology we are able to maintain liner dimension tolerances of 0,05mm on inner and outer bores, a level of accuracy and consistency that is difficult to match with thermosets such as PTFE.

Another advantage of the FluorTEP polymer is the easy processability compared to PTFE.

The properties described below provide an illustration of the physical and commercial advantages of Piltec automotive control cable liners.

To meet specific automotive standards, our up-to-date production equipment is fitted with the latest continuous in-line laser sizing equipment and as a result of this technology we are able to maintain liner dimension tolerances of 0,05mm on inner and outer bores, a level of accuracy and consistency that is difficult to match with thermosets such as PTFE.

Recent Comments